Innovative Optical Sensor Solutions for Extreme Environments

Our story…

began in 2012 with a simple but ambitious idea: that optical sensing could go far beyond its perceived limits—into environments that were hotter, deeper, harsher, and more demanding than existing technologies could survive.

That vision…

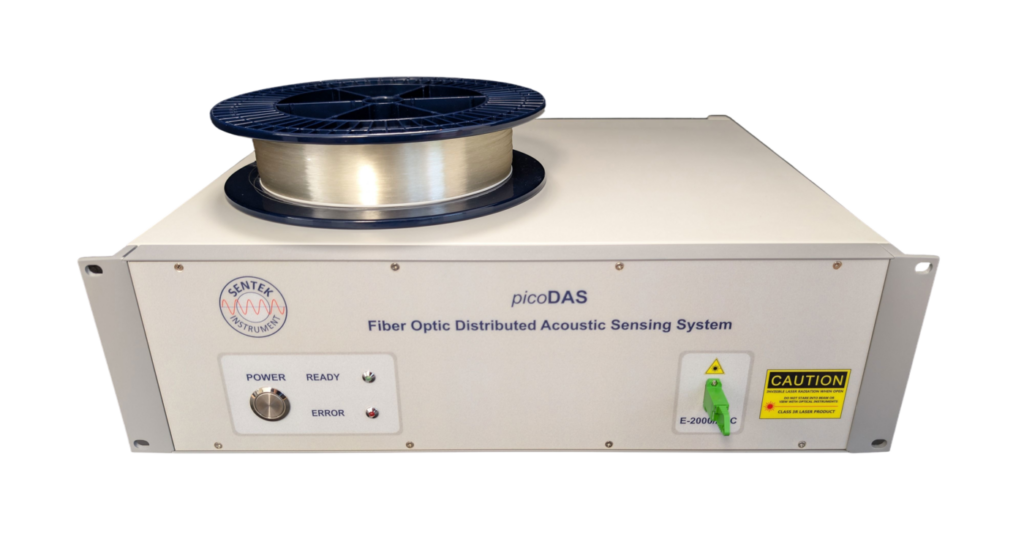

was first validated through an NSF SBIR Phase I award, supporting the development of a new approach to distributed acoustic sensing. That early work laid the foundation for what is now our picoDAS™ platform and set the trajectory for a company focused on solving the hardest sensing problems, not the easiest ones.

From the beginning…

we chose to fish in deep water—technically and commercially. Rather than incremental improvements, we pioneered an integrated suite of technologies designed to operate where conventional sensors fail. This included:

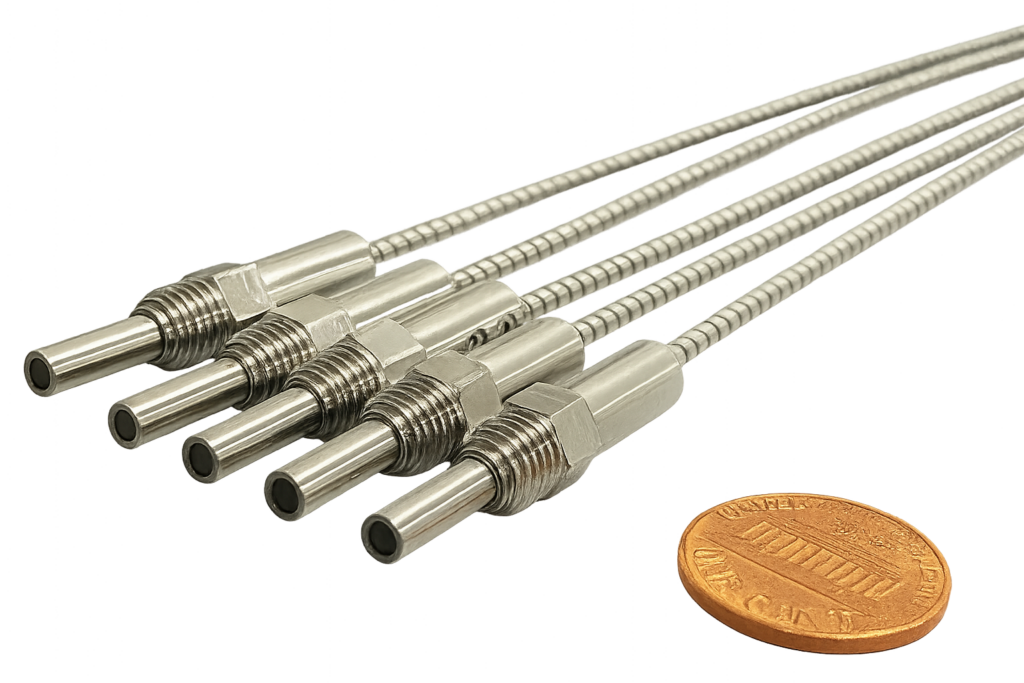

- Monolithic single-crystal sapphire pressure and temperature sensors capable of extreme environments

- Loss-countered, engineered optical fibers designed for long-range, high-fidelity signal transmission

- High-performance, cost-effective interrogators engineered to unlock the full capability of sapphire sensors and advanced fibers

This Work…

was not built in isolation. The scientific roots of our sapphire technology trace back to pioneering research conducted at Virginia Tech, where our founder demonstrated several industry firsts — including the first sapphire-fiber interferometer, the first wafer-based sapphire sensor operating at temperatures up to 1600 °C, and the first hermetically sealed sapphire Fabry-Perot cavity for pressure measurement. These breakthroughs became the technical DNA of the company. By 2016, our sapphire pressure and temperature sensors were deployed in their first pilot downhole test, marking a major milestone in transitioning from laboratory innovation to real-world operation. In parallel, the company continued to push the boundaries of distributed sensing, building on some of the earliest downhole DAS installations dating back to 2000, including applications in well monitoring and micro-seismic event detection.

Over Time…

this sustained focus on deep-tech innovation led to a fully realized sensing platform. In 2024, we launched the NovaPT-E, bringing together years of development in sapphire sensors, engineered fibers, interrogators, and software into a robust, deployable solution for demanding industrial environments.

Today…

we are a vertically integrated company, designing and manufacturing everything in-house — from sapphire mechanical and chemical processing, to specialty fiber fabrication, sensor assembly, interrogator hardware, and software. This integration gives us unmatched control over performance, quality, and reliability, while enabling rapid innovation and customization for our customers. More than a decade after our founding, our mission remains unchanged: to deliver optical sensing solutions that perform where others cannot — and to continue pushing the boundaries of what is physically and commercially possible.

Our Products

Sentek Instrument incorporates patented sapphire technology in every high-performance optical high temperature pressure sensor and downhole pressure sensor we manufacture. Our sensors, optical distributed acoustic sensing systems, and custom Fiber Bragg Grating (FBG) arrays are designed for single-point or distributed sensing in a wide range of harsh environments. The rugged design withstands flammable or explosive surroundings, severe electromagnetic interference, high-energy radiation, and challenging chemical conditions.

Our product line provides the ideal tools for temperature and pressure sensing systems in:

- Oil, gas and geothermal wells

- Advanced electric power generation systems

- Nuclear power generation systems

- High-temperature chemical or industrial processes

- Laboratory R&D applications

Our Core Competencies Include:

- Custom FBG fabrication in any fiber through any coating

- Disruptive sensor products for downhole and aerospace markets

- Proprietary optical interrogators for multiple channels and multiple sensor readings

- World’s most sensitive distributed acoustic sensing system

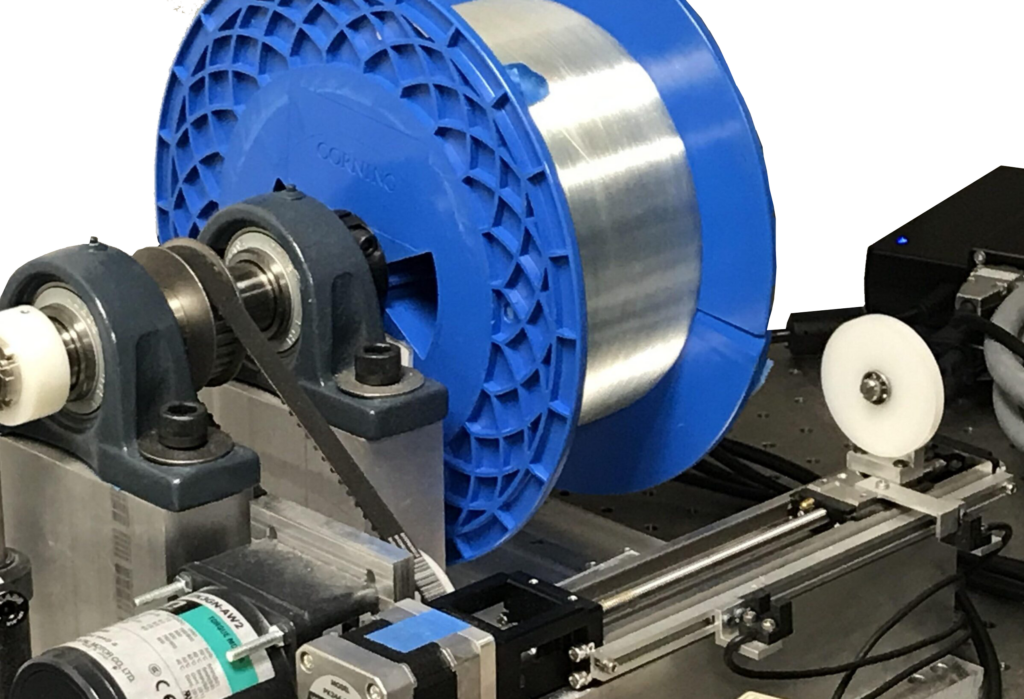

Our Process

Sentek Instrument manufactures all of our products in our state-of-the-art, vertically integrated facilities for special optical fiber fabrication, material processing, sensor fabrication, and optoelectronic instrument development. This gives Sentek Instrument complete control of the manufacturing process, from processing the raw sapphires to engineering the optical fiber and housing. Combined with our in-house expertise in embedded system and computer software development, Sentek Instrument achieves the shortest cycle from innovation to design validation, commercialization and volume production.

Located in the Virginia Tech Corporate Research Center in Blacksburg, Virginia, Sentek Instrument delivers cutting-edge, cost effective and robust sensing solutions to the market.

Our Clients